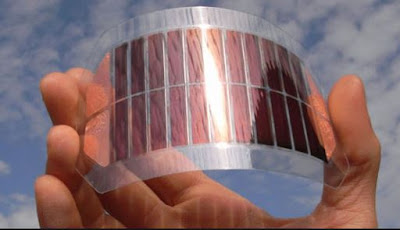

Organic Solar Cell| Photo: IITB Monash

In future, energy consumption is going to rise continuously especially amongst developing countries that aspire to have the same benefits as developed countries. One major potential contributor to the overall energy picture is to harvest solar energy, as it is a highly abundant resource.

A majority of solar panels used at homes and businesses are standard silicon solar panels. They weigh around 20 to 30 kg which limits their application. However, there is an alternative which is lightweight and more flexible- Organic Solar Cells (OSCs).

Unlike Photo Voltaic (PV) which has a high carbon footprint , OSCs are much greener. Moreover, OSCs are flexible and lightweight and they can be used in locations inaccessible to the heavier silicon PV. They can be printed and stuck onto buildings, car windows and can also be used for mobile charging

The recent increase in the efficiency of organic solar cells to 26% in low light by Armor- a French organic PV specialist, has put more onus on this technology.

With climate change happening right now, it has become more crucial for countries to invest in renewable energy and cut down their fossil fuels budget. But even amongst renewable energy, there are differences on how green they really are.

OSC promises low carbon footprint

One of the major causes of climate change due to CO2 and other greenhouse gases (GHGs) is burning fossil fuels. However, replacing fossil fuels with renewable sources of energy is not sufficient. The creation and operation of renewable energy sources result in CO2 emission and other GHGs.

CO2e(CO2 and other GHGs) emission per kilowatt-hour for fossil fuel sources is approximately 400-500 g kWh-1. For renewable sources, the values are much lower but not negligible.

In case of silicon photovoltaics, values differ according to the technology and location of manufacturing- with values roughly around 50 gkWh-1.

In the manufacturing of traditional solar panels, metallurgical-grade silicon is purified into polysilicon which creates silicon tetrachloride. Recycling tetrachloride to extract silicon needs less energy but the reprocessing equipment required is quite expensive.

Some industries discharge the byproduct into water streams. If exposed to water, silicon tetrachloride releases hydrochloric acid, acidifying the soil and emitting harmful fumes.

In the case of OSC, the carbon footprint is less. According to Dr Karl Leo, professor at Technische Universität Dresden, Germany, OSCs can reduce carbon footprint “dramatically, and it has a super-low CO2 emission.”

A study by German testing institute- TÜV Rheinland, revealed that carbon footprint from OSC is 14.52 kg CO2e per square metre. The study took into account OSCs produced by German based technology leader in organic photovoltaics, Heliatek.

It also revealed that the organic solar films allow to recover the CO2e arising during the entire life cycle (from manufacture to disposal), after less than 3 months.

How do OSCs work?

Picture: Sigma Aldrich |

OSCs on the other hand when exposed to light generates electric current. They are made up of multiple layers, one of them is the acceptor layer. When OSC is exposed to sunlight, an electron is released from the layer of organic molecules. The acceptor layer’s job is to pass that electron onto the electrode. This leads to build-up charge which generates electricity.

The most common material used for acceptors in OSC is fullerene- a molecule composed of 60 carbon atoms joined together in a structure. However, the efficiency with fullerene acceptor is limited to 10% due to which many researchers are looking for non-fullerene alternatives.

Dr Soumitra Satapathi, associate professor at IIT Roorkee told CarbonCopy that the current thrust of the research is the development of low bandgap polymers and non-fullerene acceptors. In addition to these, small molecules which are capable of showing singlet fission-an exciton(electron-hole pair) multiplication process can significantly improve the efficiency of OSCs, he said.

Will OSCs replace silicon solar cells?

With excellent stability, low generation cost of electricity and high efficiencies of above 20%, crystalline silicon solar is dominating the Photovoltaics (PV). In spite of being lightweight and flexible, OSCs are not able to compete with PV in all the three parameters.

According to Leo, “They (OSCs) are addressing very different markets where lightweight and flexibility are asked for, e.g. in building integration.”

OSCs have to carve a new niche for themselves where they can replace inorganic PV technologies. One of such niches is building-integrated photovoltaics (BIPVs) where OSCs can be used on the roofs and walls of storage buildings.

Since BIPVs are designed to carry lighter loads, crystalline silicon modules are not appropriate for them. However, OSC as a plastic foil with a surface density of less than 1 kgm-2 can be used because it weighs at least ten times less than crystalline silicon modules.

In spite of the small market for BIPV as compared to the PV, BIPV could still reach a market size of USD 59.5 billion by 2028 which is a very attractive quickly growing market.

Owing to their flexibility, OSCs can also be used for consumer applications such as clothing, bags and in camping products.

Despite being limited to some niches, it is interesting to speculate whether OSCs will be able to enter the mainstream PV market. According to Leo, “In the very long term, if organics would reach very high efficiency, they might compete, but this is not very likely in the near and mid-term.”

A study published last year pointed out that OSCs can only compete with crystalline silicon if it reaches the following parameters- “module efficiency around 20%, lifetime of more than 20 years, and cost well below silicon.”

Results from laboratories and companies show that OSC can reach a ‘20 years lifetime’ perimeter most easily. Cost-wise OSC is more expensive than mainstream technology crystalline silicon, the study noted.

According to the study, the cost difference is not surprising since all tools and materials for OSC are mass-produced for the first time whereas silicon PV has been in the market for a long time.

OSC research in India

The Council of Scientific and Industrial Research (CSIR)- National Physical Laboratory has taken many research and development activities for the development of “efficient stable solar cells”.

According to the data, CSIR group has started working in design and synthesis of donor and acceptor materials for organic solar cells to improve the power conversion efficiencies and lifeline of devices.

Many institutes in India are also working on OSC. Researchers from the Indian Institute of Technology, Kanpur have developed 12x12 cm2 sub-modules from organic solar PV cells on a paper substrate. It can be used to power flexible electronic devices under an indoor lighting environment.

OSCs market trends

India imports around 80% of its solar cells and modules from China along with other equipment. Many projects in India and worldwide were delayed due to the initial lockdown of manufacturing activities in China, followed by lockdowns implemented in other countries, the report stated.

In 2019, BIPV segment held a majority of organic cells market share followed by portable electronics, the report highlighted. It said that better government policies and guidelines regarding enhanced renewable installation are going to reinforce BIPV installations in the coming time.

Will OSC be overshadowed by perovskite?

Perovskite is a rapidly expanding class of solar cells. There has been a lot of research going on because of their high efficiency- even higher than silicon in some cases.

It was found viable for PV 10-12 years ago, said Don Scott, business development director at Power Roll- a UK-based flexible solar film developer, adding, since then the amount of research and efficiency has gone up dramatically- from 1-2% to 16-17% in the labs.

“Compared to any material in the history of PV, the curve of perovskite has seen the fastest advancement in efficiency in the shortest amount of time,” he said.

However, there are some major bottlenecks related to perovskite. One of them is stability. They are highly sensitive to ambient air and moisture and they break down quickly on exposure. To protect them, they have to be put inside an encapsulation film as soon as they come out from the plant.

Another challenge is the use of toxic lead which is a concern from an environmental perspective.

Scott is not sure whether OSCs will be overshadowed by perovskite in the future but he emphasized that a lot of research is going on to overcome the challenges of perovskite.

Karl is of the same opinion as Scott. According to Karl, “Perovskite has super-high efficiency, but currently, they contain lead which is unacceptable for many. Furthermore, there are stability issues.”

OSC for developing countries

India receives sunshine for around 250 up to 300 days per year which puts it in a good position to harness solar energy to meet the rising electricity demand. The country receives approximately 5000 trillion kWh solar energy annually.

It has pledged itself to fast and large-scale renewable energy capacity addition. Under the nationally determined contributions (NDCs) India aspires to achieve 40% share of installed power generation capacity from non-fossil fuel sources by 2030.

The country wants to increase its solar capacity to 280 GW by 2030-31 from about 39 GW currently, making it over a third of its overall power requirement. India is chasing a renewable capacity target of 175 GW by 2022 and 450 GW by 2030, from about 93 GW currently, as part of its commitment under the Paris Climate Accords.

With an efficiency of above 20%, crystalline Si solar cells rule the market. However, these cells consume a large amount of energy in the manufacturing process- extremely hot furnaces around 1,500 degree C are needed to develop high purity silicon. This increases the payback time.

Unlike Si solar technology, OSCs are less energy-intensive and owing to their thinness and flexibility they can be manufactured by simply printing the layers of the cell onto a backing such as paper and plastic.

OSCs usually have lower energy payback time (few months) than silicon solar cells (2-3 years) considering its cost-effective fabrication process, said Satapathi, adding, therefore, India has huge potential in this technology.

According to him, this will be helpful for building-integrated photovoltaics, portable electronics, defence and also Internet of Things (IoT) devices.

For developing countries that do not have access to electrical grids and the finance to build one, OSCs are a great alternative. With low upfront investment and certainly low product shipping costs, OSCs can provide electricity in smaller quantities required for mobile charging, home lighting and in textile industries.

Additionally, if PV solutions require very skilled engineers for installation, it is going to be a problem for people living in rural areas and farmers because of the complications and cost involved, said Scott.

According to him, “For a developing country like India, we need to bring the cost way down and bring ease of use way up. If we are able to do that we can enable new markets, new application of OSC right at grassroots of people's daily life”

This report on the Automotive Cyber Security Market studies the factors that influence its functioning and includes a detailed explanation of the future speculations. The report takes the years 2017 and 2018 for historical analysis, 2019 is taken as the base year, and the years 2020 to 2027 are taken as the forecast period. This report helps readers planning to invest in the sector by giving a detailed evaluation of the regional landscape and a comparative study. The report also highlights future trends deduced by assessing historical data in this report

ReplyDelete